charpy impact test slideshare|charpy impact test procedure : distributors This document discusses impact testing techniques used to evaluate the fracture behavior of materials. It provides background on impact testing and describes the Charpy and Izod impact tests. These tests involve . 20 de jun. de 2021 · RIO — Condenada a 16 anos e três meses de prisão por ter matado e esquartejado o marido, a ex-garota de programa Elize Kitano Matsunaga, de 39 anos, está de volta às barras do tribunal. Ela .

{plog:ftitle_list}

Resultado da Xvideos. Sexo lesbica novinha transando com a amiga, caindo de boca na buceta dela e chupando todinha. Uma loirinha linda de apenas 18 aninhos, colando velcro com uma morena gostosa que estava molhadinha de tesão. Elas começam o ensaio se beijando na boca, logo partem para o sexo .

The Charpy impact test determines the impact toughness or strength of a material by measuring the energy absorbed when a pendulum strikes a V-notched specimen. Testing .This document discusses impact testing techniques used to evaluate the fracture .

The Charpy impact test determines the impact toughness or strength of a .

This document discusses impact testing techniques used to evaluate the fracture behavior of materials. It provides background on impact testing and describes the Charpy and Izod impact tests. These tests involve . Impact testing is necessary to measure impact energy and toughness by determining the ability of a material to absorb energy without breaking. The two main impact test methods described are the Charpy test .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different .

charpy impact test sample

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

The Charpy impact test determines the impact toughness or strength of a material by measuring the energy absorbed when a pendulum strikes a V-notched specimen. Testing was conducted on specimens at room .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .

charpy impact test procedure

3. International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 – 6359(Online) Volume 4, Issue 4, July 2. FINITE ELEMENT MODEL The impact test apparatus is .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The . 5. Types of materials for impact testing Nearly all materials may benefit from impact testing, but the most common types used are metals, plastics, woods, composites, ceramics, and polymers. Generally these .

Charpy Impact Test: The belief of the test differs from that of the Izod test in that the test piece is tested as a beam supported at each end a notch is cut across the middle of one face, and the striker hits the opposite face directly behind the notch. When the results of a number of tests performed in different temperatures are plotted . 4. Impact test report percent shear (fibrous) fracture on the fracture surface, or the change in the width of the specimen (lateral expansion). Figure 2: Charpy v-impact test The notched-bar impact test is most meaningful when conducted over a range of temperature so that the temperature at which the ductile-to-brittle transition takes place can be determined.

In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area. At present, the measurement of absorbed energy and lateral expansion is quantitative and well defined, but the methods used by most laboratories in the measurement of percent shear are qualitative and .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.

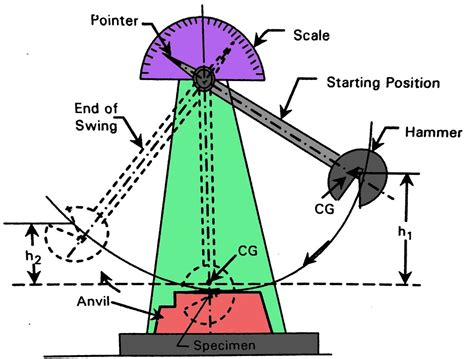

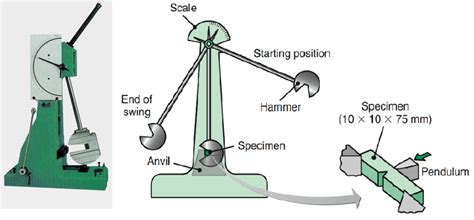

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized. They were one at a time properly placed within a .The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value. 4. IS : 1499 - 1977 Indian Standard METHOD FOR CHARPY IMPACT TEST (U-NOTCH) FOR METALS ( First Revision ) 0. F O R E W O R D 0.1 This Indian Standard (First Revision) was adopted by the Indian Standards Institution on 15 November 1977, after the draft finalized by the Methods of Physical Tests Sectional Committee had been approved by the .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

charpy impact test pdf

The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .

It describes the apparatus, testing procedures, significance, and interpretation of results for Charpy impact testing. Charpy impact testing involves breaking a notched specimen with a single blow from a pendulum to determine the material's resistance to brittle fracture. The document provides details on specimen preparation, conditioning . APPENDIXES (Nonmandatory Information) X1. NOTES ON SIGNIFICANCE OF NOTCHED-BAR IMPACT TESTING X1.1 Notch Behavior: X1.1.1 The Charpy V-notch (CVN) impact test has been used extensively in . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is . Impact Testing Equipment Izod and Charpy are the most common tests. Both employ a swinging pendulum and conducted on small notched specimens. The notch concentrated the load at a point causing failure. Other .

Pendulam impact test - Download as a PDF or view online for free . B.2. APPARATUS:- 1. Impact testing m/c, 2. Charpy test specimens of mild steel, Brass, Aluminum, 3. Vernier caliper, 4. Specimen setting fixture. B.3. THEORY:- In charpy test, the specimen is placed as ‘cantilever beam’. The specimens have V- shaped notch of 45 . Temperatura: Las propiedades de tenacidad de un material pueden variar con la temperatura. Algunos materiales pueden volverse más frágiles a temperaturas bajas. Procesamiento térmico: Los tratamientos térmicos, como el temple y el revenido, pueden alterar las propiedades de tenacidad del material. Conclusión. La prueba de impacto Charpy es una . 4. Two types of material testing!!! • Destructive Testing/Mechanical Tests – • The material may be physically tested to destruction or indentation. • To measure the strength, hardness, toughness, etc. • Example: Tensile testing, Impact testing, Hardness Testing etc. • Non-Destructive Tests (NDT) • Samples or finished articles are tested before being used and . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

microtech compression tester

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized. 2. Charpy Test Specimens According to ASTM Standard E 23, “Standard Test Methods for Notched Bar Impact Testing of Metallic Materials”, Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be: • V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along .

シャルピー衝撃試験機. シャルピー衝撃試験(シャルピーしょうげきしけん、英: Charpy impact test )とは、切り欠きのはいった角柱状の試験片に対して高速で衝撃を与えることで試験片を破壊し、破壊するために要したエネルギーと試験片の靭性を評価するための衝撃試験である。 The Charpy impact test determines the impact toughness or strength of a material by measuring the energy absorbed when a pendulum strikes a V-notched specimen. Testing was conducted on specimens at room temperature (24.3°C) and -40°C. The room temperature specimen absorbed more energy (17.33J) and was more ductile, while the -40°C .

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials.The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, Instron Ceast 9050 impact tester, and microscope. It also outlines the step-by-step procedure for setting up and performing an impact test, which .

microtech rotary compression tester

EncurtaNet. Este Domínio pertence a Encontrou Algum Problema? Entre em contato com [email protected]

charpy impact test slideshare|charpy impact test procedure